Virtual Reality

Immersive Laboratory Training At Boehringer Ingelheim

Leading pharmaceutical company Boehringer Ingelheim promotes hands-on learning by enabling its employees to practise independently, safely and without using scarce resources in previously inaccessible laboratories thanks to VR.

Success Story

VR training platform enables Boehringer Ingelheim to learn faster and more safely

Challenges

Highly Limited Access options

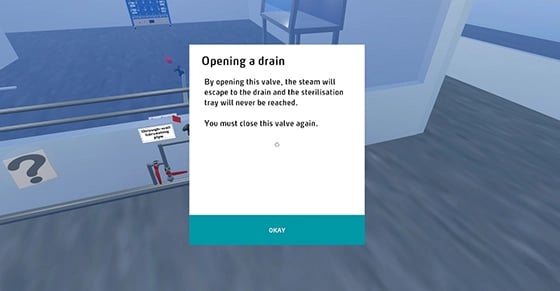

Working in a laboratory involves several potential hazards such as burns and explosions.

Learning safety rules and procedures is therefore essential. However, laboratories are usually at capacity and some even require training to enter.

As a result, access is severely limited, and many learning tasks must be ' mapped out' in theory at present.

.webp?width=560&height=292&name=Boehringer%20Ingelheim%20(2).webp)

Solution

.webp?width=560&height=291&name=Boehringer%20Ingelheim%20(4).webp)

With the help of 3spin Learning, Boehringer Ingelheim easily creates a VR lab training allowing new employees to get to know their future working environment from day one.

Independent And Safe VR Training

3D models or highly realistic 360 degree photos can be turned into an interactive scenario for VR glasses and desktop PCs. This allows employees to practice their skills for as long as they need to master protocols and processes.

Results

Immersive learning scenarios as simple as a PowerPoint presentation

Independent and safe learning

Making inaccessible laboratories virtually usable

Unlike pure “imagination”, VR modules enable hands-on training. Boehringer Ingelheim thus significantly increases learning success, reduces resources and expects a reduction in training time from many months to just a few weeks.

VR & AR Default Tool

In addition, 3spin Learning turns VR & AR into a standard tool with which all Boehringer Ingelheim employees can learn and create simulations even without programming knowledge.

Now is the time for VR and AR to be developed as universally usable learning technologies: with the 3spin Learning learning platform, immersive scenarios can be created and used as easily as a PowerPoint presentation."

Innovation Project Specialist, Boehringer Ingelheim

Discover How Immersive Learning With AI Will Contribute To Your Success

Choose your preferred date and get a free consultation:

A personal and non-binding product demonstration

A specific assessment of your particular requirements

Hands-on insights into industry-specific case studies